To really make the product interesting you should think about painting or decorating it. The key raises the flexibility of the units which can make it probable in order for them to simply bypass materials that other materials can’t. Because the systems are produced from a sizable proportion of aluminum it is possible to recycle them an individual will be done with them or they have been damaged.

For their several great features, the aluminum composite sections may be used in different areas.  One of many applications of the panels is in inside use where you use them in designing the inner of one’s house. The PVDF covering on the models is sturdy ergo you do not have to be concerned about the panel fading. It is possible to flip the materials to any of your preferred shape applying easy tools. Due to these features, you need to use the systems in tips, surfaces, noise-barrier walls, track coaches, false roofs, interior walls, escalator cladding and a number of other places.

One of many applications of the panels is in inside use where you use them in designing the inner of one’s house. The PVDF covering on the models is sturdy ergo you do not have to be concerned about the panel fading. It is possible to flip the materials to any of your preferred shape applying easy tools. Due to these features, you need to use the systems in tips, surfaces, noise-barrier walls, track coaches, false roofs, interior walls, escalator cladding and a number of other places.

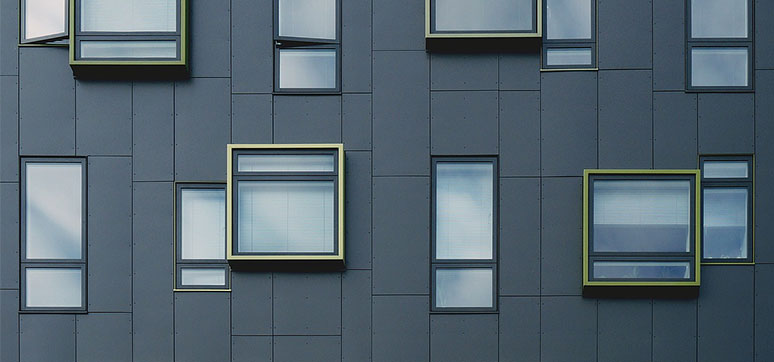

The difficult nature of aluminum composite panel and their fire tolerant character makes it well suited for outside use. You need to use it in numerous areas such as for example factory houses, petrol pumps, coach stands, shopping centers, sports stadiums, airports, vehicles, bridge cladding and many other areas. The flat refined look of the systems also makes them an ideal prospect for signage use. You are able to sue them for path, protection, shopping mall, industrial, company, college, factory, nameplate, and actually way signage.

Aluminum composite panel , abbreviated as ACP panel , is actually a structure of three layers. Since the low-density core is placed between two slim skin layers, it may also be called meal panel. The skin levels are aluminum blankets and the low-density key is just a non-aluminum core. The sandwich startup helps ACP sections to be great for mechanical uses. It stands out of the different metallic systems for outstanding mechanical efficiency at little weight. Meal systems have considerable uses due to their large rigidity.

For decades, Aluminum blend systems have been used to manufacture equally military airplane and private aircraft. Nowadays, these are used in racing cars, vessel buildings and custom architectures. A contemporary civil aircraft can contain as much as 5-15% composite panel. The proportion might raise as much as 50% in new Boeing 7E7 aircraft. The light-weight and ideal toughness would make that airplane outstanding. As a result of amount of great features, the ACP systems can be employed in different areas.

The acceptance and achievement of composite engineering in the automotive and aviation business have caused it to be attractive to another industries seeking to really have the most readily useful benefits of it. Here ACP panels have now been going for a substantial place. The Aluminum blend panels are light than steel.

In the event of an inside decor, it plays an important role. The PVDF finish onto it helps it be durable and resilient to elemental attacks. Their unique freedom enables you to use these in tips, inside surfaces, aeroplanes, partitions, rail instructors, fake roofs, noise-barrier walls, escalator cladding and a number of other places.

Besides, you should use it for external designs. It will truly beautify your exterior. This is the reason using an Aluminum composite panel in factory structures, petrol pushes, activities stadiums, outdoor homes, bus stands, malls, vehicles, airports, and link cladding are always good. For the level finished look, it is applied as signage. The glittering quality generally brings onlookers’attentions.

Recent Comments